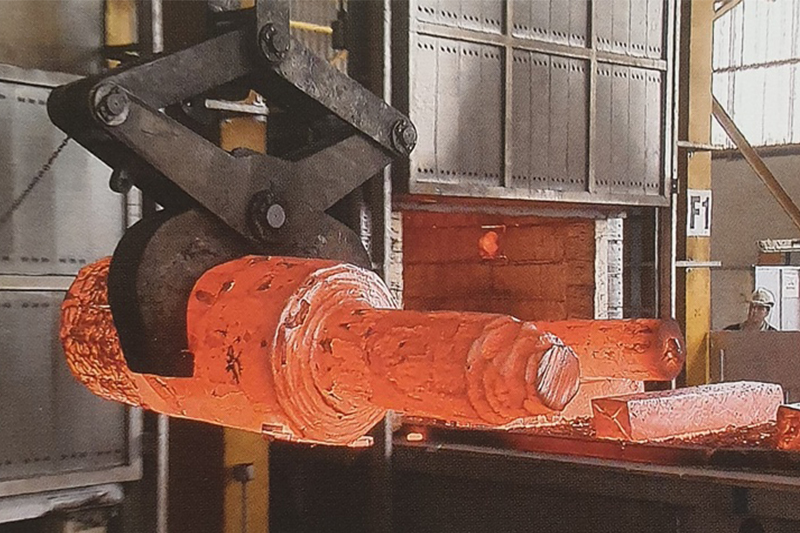

We provide tailor made or standard all steel cast and cast products (including pipes, rolls, liners) defined by DIN-EN 10293, duplex/superduplex, stainless steel, adamite, sferoidal and acicular iron and ductile iron. Castings can be supplied from 5 kg up to 25 tons single piece in as cast, finished machined or assembled form.

Our supply scope includes also centrifugal casting and open die forging parts.

The parts we supply is carried out a simulation with the state-of-the-art technological applications taking into account the customer’s demands before casting, the recession zones and hot spots are determined. The casting process is carried out in one time without faults and deficiencies. At the foundry; precision steel alloys, pieces with tons of weight which require strength and durability are prepared and cast carefully. Horizontal and vertical centrifugal casting methods, Bi-metal castings that require special technique and knowledge are meticulously performed. Both the 25-ton piece and the 5kg piece are processed with the same precision